ROTARY VACUUM DRUM FILTER

FILcare is a manufacturer and supplier of Rotary Drum Vacuum Filters for several industries. Our drum

filters are used in various industries including mineral processing, chemical, pharmaceutical, Paper, food

and beverage.

We can custom design drum filters to suit your process needs.

MAIN APPLICATIONS OF ROTARY DRUM VACUUM FILTERS

- Alumina refineries

- Iron ore refineries

- Gold refineries

- Dewatering in gold, nickel, cobalt, graphite refineries

- Titanium Dioxide (TiO2) production

- Pharmaceutical and food dewatering applications

- Chemical dewatering applications

- Lime mud filtration

- Paper Industries

When is Rotary Vacuum Drum Filter Used?

Rotary drum filters are usually used for continuous dewatering of slurries with coarse aggregates. Drum

filters are suitable for slurries with high solids contents (2-40 wt. %).

Either cake or filtrate can be the filtered product.

How FILcare Rotary Drum Vacuum Filters Work

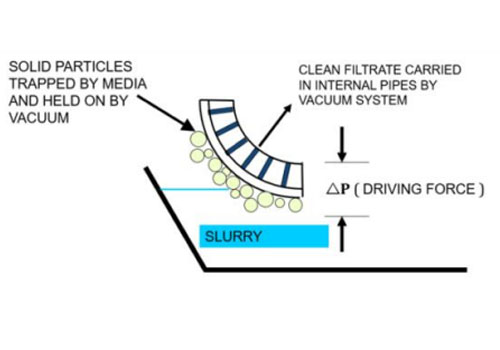

This filter type consists of a cloth covered drum rotating in a tank. The surface of the drum is divided into

several compartments which are connected to an automatic valve for vacuum application.

The slurry is fed continuously to the tank. Level in the tank and submergence of drum is maintained by

adjustable overflow weir or through level regulation system

As the drum rotates, each compartment goes through the same cycle of operation: filtration, cake drying,

de-watering & cake discharge, cloth cleaning.

Vacuum is applied to submerged segments, which causes the mother liquor to flow through the filter cloth,

while solids build up on the cloth to form the cake.

As sections emerge from the tank, the vacuum de-waters the cake.

When all mother liquor has been removed, the vacuum is automatically cut off and the cake is discharged

from the drum.

Filter cake Discharge Systems

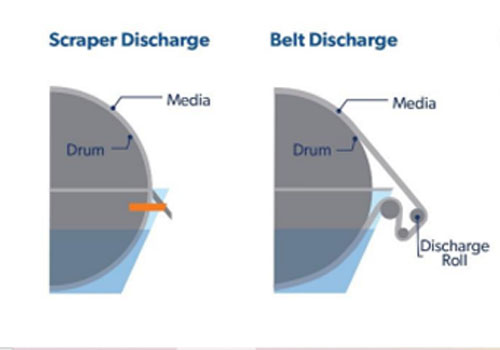

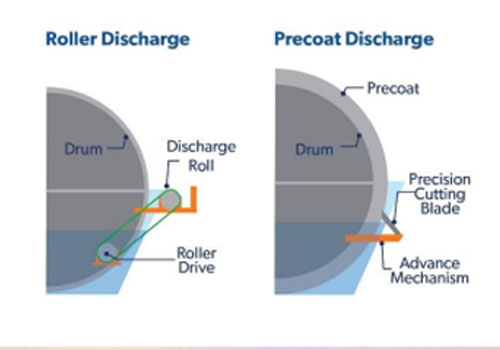

FILcare drum filters are available in five different cake discharge systems: Scraper, Roller, String, Belt, Knife advance – pre coat. The drum filters pre coat system may enhance filtrate clarity or assist with cake build up.

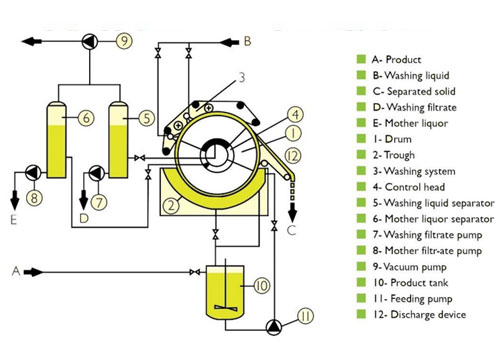

Filter Installation with Cake Washing and Filtrate Separation :

System with a vacuum drum filter equipped with two filtrate separators, pressure belt and cake washing process, as most complicated example. In case the washing is not necessary, or a separation between the mother liquor and the washing filtrate is not requested, the installation could be equipped with one filtrate separator only. The filtrate pump at the separator can be excluded if sufficient barometric height exists for the discharge process.